Surveillance du traitement thermique dans les conteneurs de fret

Le traitement de conteneurs destinés à voyager à l'étranger nécessite une fumigation ou une alternative pour garantir qu'aucun organisme vivant ne soit transporté accidentellement. Ce traitement est effectué au port avant l'exportation de la cargaison. Lors de l'utilisation d'un traitement thermique, il est crucial de surveiller la température à l'intérieur du conteneur avec un capteur de température, pour vérifier que la température reste réellement au seul minimal ou qu'elle y soit légèrement supérieure.

Dans cet article, nous discuterons des avantages du traitement thermique et pourquoi la surveillance de la température à l’intérieur du conteneur est essentielle.

Pourquoi le traitement thermique des conteneurs de fret est-il nécessaire ?

Les marchandises sont souvent expédiées sur des palettes en bois, une matière qui a tendance à attirer toutes sortes d’insectes. Pas de problème lorsque les marchandises sont expédiées dans la même zone, mais cela peut devenir dangereux lorsque les marchandises sont exportées vers d’autres continents. Les insectes indigènes peuvent devenir des espèces envahissantes dangereuses qui mettent en danger les écosystèmes et l’agriculture.

Lorsque des marchandises sont expédiées partout dans le monde, des passagers clandestins peuvent s'inviter dans votre cargaison. La punaise marbrée (BMSB) est l'un de ces passagers bien connus et indésirables. Ces insectes sont particulièrement interdits en Australie et en Nouvelle-Zélande. Mais les insectes ne sont pas les seuls à constituer un risque : les moisissures, les micro-organismes, les reptiles et les petits mammifères peuvent également propager des maladies dans leur pays d'accueil.

Pour tuer les punaises marbrées et autres nuisibles, les conteneurs doivent être traités. On appelle ce processus « fumigation ». Ce traitement a lieu dans le pays d'origine où les marchandises quittent le port.

Les dangers de la fumigation

Si le bromure de méthyle, un gaz toxique, était auparavant utilisé pour désinfecter les conteneurs maritimes, il s’est avéré plus nocif que prévu. Il éradique les parasites présents dans le conteneur, mais est également nocif pour les travailleurs qui doivent inspecter la cargaison. Le bromure de méthyle est toxique pour l'environnement et est aujourd'hui interdit dans certaines parties du monde. Le gaz a également tendance à polluer l’air et le sol où il se disperse. Une petite quantité suffit pour causer de graves dommages au système nerveux central, ainsi que différents types de lésions cérébrales et pulmonaires. Elle affecte même la couche d’ozone.

Une alternative à la fumigation est attendue depuis longtemps.

L'alternative : le traitement thermique

Un traitement alternatif à la fumigation aux gaz toxiques est le traitement thermique. Au cours de ce processus, le contenu d’un conteneur de fret est chauffé jusqu’à 56°C. Cela nécessite que l'intérieur atteigne minimum 60°C pendant au moins 30 minutes. Ce processus tue ainsi les insectes tels que la punaise marbrée, ainsi que leurs œufs et leurs larves.

Il est important de noter que si la température intérieure de 56°C n’est pas atteinte et maintenue pendant 30 minutes, le traitement est considéré comme un échec. La surveillance à distance de la température est donc cruciale pour garantir l’éradication des éventuels nuisibles.

Les avantages du traitement thermique

L’avantage du traitement thermique des conteneurs par rapport à la fumigation classique est qu'il n'utilise plus de gaz dangereux et toxiques. Il est nettement plus respectueux de l’environnement et plus facile à gérer après le traitement : le dégazage n’est pas nécessaire et le personnel peut pénétrer dans le conteneur en toute sécurité. Bien entendu, un traitement à haute température n’est possible que lorsque les marchandises transportées peuvent résister à cette chaleur élevée.

Une fois le traitement thermique du conteneur terminé, celui-ci est simplement ouvert pour permettre à son contenu de refroidir à la température ambiante. L'emballage est marqué d'un tampon HT spécial et les documents et certificats nécessaires pour l'expédition sont octroyés. Le conteneur est refermé et est prêt à être exporté.

Surveillance des traitements thermiques

Le traitement thermique du conteneur est surveillé en plaçant plusieurs capteurs de température au cœur de la cargaison pour enregistrer la température dans les endroits les plus froids. La température est enregistrée : le conteneur peut avancer dès que les valeurs minimales sont maintenues avec succès.

La surveillance du traitement thermique des conteneurs de fret avec plusieurs capteurs permet une mesure plus exacte et précise des gradients de température et de la répartition au sein du conteneur. Elle garantit que toute la cargaison est chauffée uniformément. Elle permet également d'identifier les points chauds ou froids potentiels, et ainsi d'ajuster le processus de traitement thermique pour plus d'efficacité.

Un module de capteurs de surveillance en temps réel peut enregistrer en continu la température à l'intérieur du conteneur pendant 30 minutes entières. Les données obtenues en direct vous permettent d'effectuer instantanément les ajustements nécessaires.

Lorsqu'un traitement ne parvient pas à maintenir une température intérieure d'au moins 56°C pendant 30 minutes, la cargaison ne peut pas être exportée. L’ensemble du processus devra être répété, ce qui entraînera des retards. Pour garantir le bon déroulement du processus dans le port, il est essentiel que ces pannes ne puissent pas se produire.

Notre solution pour un traitement thermique réussi

Reporter est notre système de surveillance à distance polyvalent et prêt à l'emploi. Il est doté d'une connexion Internet autonome via une carte SIM et peut fonctionner à la fois sur le réseau électrique et sur son propre panneau solaire. Le système étant mobile, il peut être utilisé dans plusieurs endroits. Reporter envoie ses données vers le cloud (Crodeon Dashboard) à des intervalles de 30 secondes ou plus. Après le traitement, toutes les données et mesures exactes peuvent être présentées à des fins d'archives.

Reporter a pour avantage de pouvoir être utilisé par tout le monde. Aucune connaissance technique n'est nécessaire et l'installation est rapide et facile.

Crodeon Dashboard

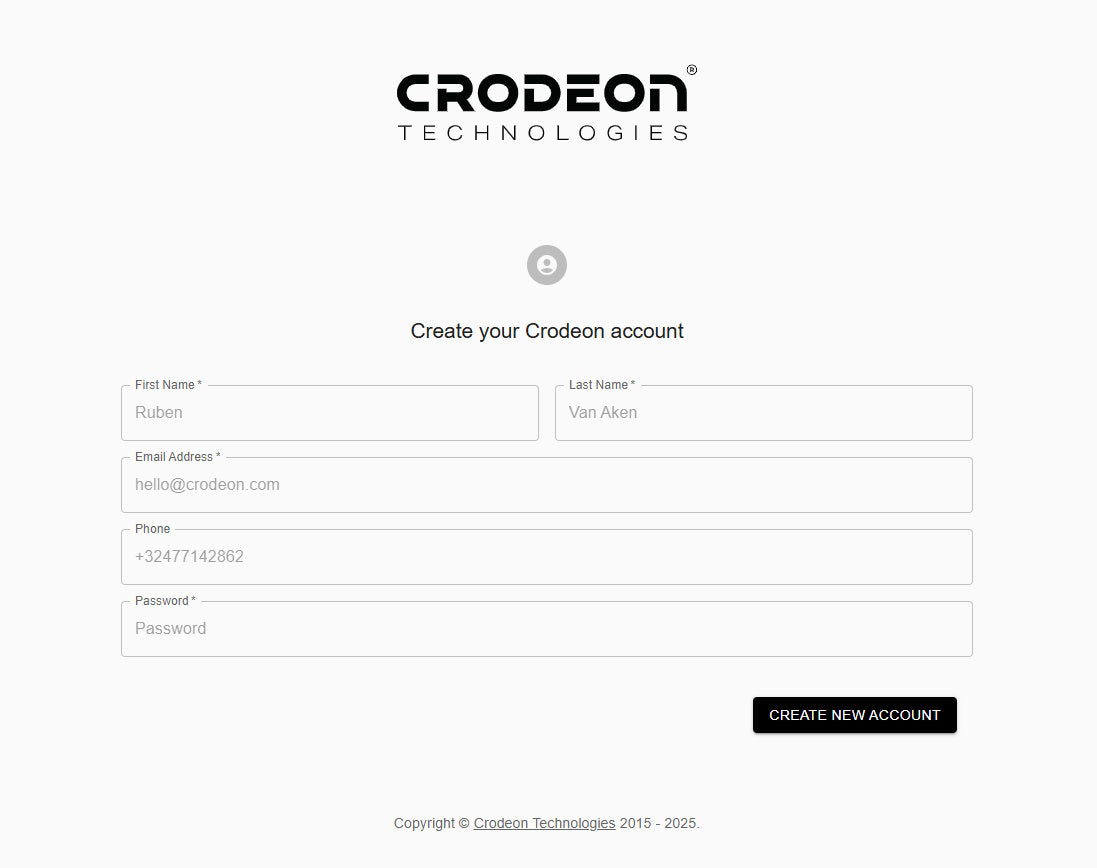

Crodeon Dashboard est une application Web à laquelle vous pouvez accéder via votre navigateur préféré. Cette plateforme cloud en ligne vous permet de modifier les paramètres du Reporter, de modifier les intervalles de mesure et d'afficher les données historiques et en direct.

Les données historiques peuvent être exportées vers Excel, afin de pouvoir être analysées en détail si nécessaire. Ces enregistrements pourraient s’avérer particulièrement précieux dans le cas où vous devriez prouver qu’un envoi a réellement été soumis à une température de 56°C pendant 30 minutes.

Commencez à surveiller vos traitements thermiques sans tarder

Vous expédiez des marchandises dans le monde entier ? Vous exploitez un port majeur ou vous réalisez des traitements thermiques ? Reporter est votre solution de surveillance à distance mobile et fiable.

Pour discuter de nos services, envoyez-nous un e-mail ou appelez Jonathan.

Sources:

Aigner, J. D., & Kuhar, T. P. (2016). Lethal High Temperature Extremes of the Brown Marmorated Stink Bug (Hemiptera: Pentatomidae) and Efficacy of Commercial Heat Treatments for Control in Export Shipping Cargo1. Journal of Agricultural and Urban Entomology, 32(1), 1–6. https://doi.org/10.3954/1523-5475-32.1.1

En savoir plus :