Why sensors disagree: slight differences in temperature explained

You are checking the temperature in a cold room, greenhouse, or server room. You hold a digital handheld thermometer next to the fixed, mounted sensor and notice a slight difference. Maybe half a degree, maybe a full degree. Your first thought: is one of these sensors inaccurate or even faulty?

This is a question we often get at Crodeon, and it's a completely reasonable one. However, a small difference between two thermometers is rarely an indication of a defect. It’s usually the expected and explainable result of different designs and technologies at play. Let’s break down the main causes.

1. Response time: fast vs. slow sensors

One of the main reasons for a temporary temperature difference is the response time. Not every sensor adapts equally quickly to changes in the ambient temperature.

Thermal mass: The size and material of a sensor determine its "thermal mass." A small, light sensor (like those in many handheld meters) has little mass and will warm up or cool down very quickly. A larger, more robust industrial sensor has more mass and responds more slowly. When the temperature fluctuates, for example, because a door or window opens, the fast sensor will respond immediately, while the slower sensor will provide a more stable, averaged reading.

Enclosure: The sensor is housed in a casing that protects it. A thin plastic casing transmits temperature faster than a durable, waterproof stainless steel (SS) casing.

Imagine the cooling system kicking in in the storage area. A fast handheld meter will immediately show the temperature drop. The fixed, slower sensor will also measure the drop but more gradually. Neither is "wrong," they just tell a slightly different story about the same moment.

2. Form factor: how the design affects the measurement

The physical shape and placement of a sensor directly impact what it measures.

Airflow: A sensor measures the temperature of the air flowing directly past it. A fixed sensor measures continuously at one specific spot. When using a handheld device, your own presence and movement affect the airflow. Are you holding the device close to a cold wall, in direct sunlight, or next to a fan? All these factors can locally influence the measurement, causing a difference compared to the fixed sensor hanging a few meters away.

3. Sensor technology and built-in tolerance

Behind every temperature measurement lies a piece of technology (e.g., a thermistor, thermocouple, etc.), and no sensor is absolutely perfect. Each sensor has a manufacturer-specified accuracy tolerance.

For example, a professional sensor might have an accuracy of ±0.2°C, while a cheaper handheld meter may have a tolerance of ±1°C. If you place these two devices next to each other, a difference of 1.2°C can still theoretically be "within specifications." When comparing two different technologies, you’re essentially adding their tolerances together.

Aim for consistency with a professional system

So, that small temperature difference is rarely a cause for concern. It’s a logical result of differences in response time, form factor, and the built-in tolerances of the sensors.

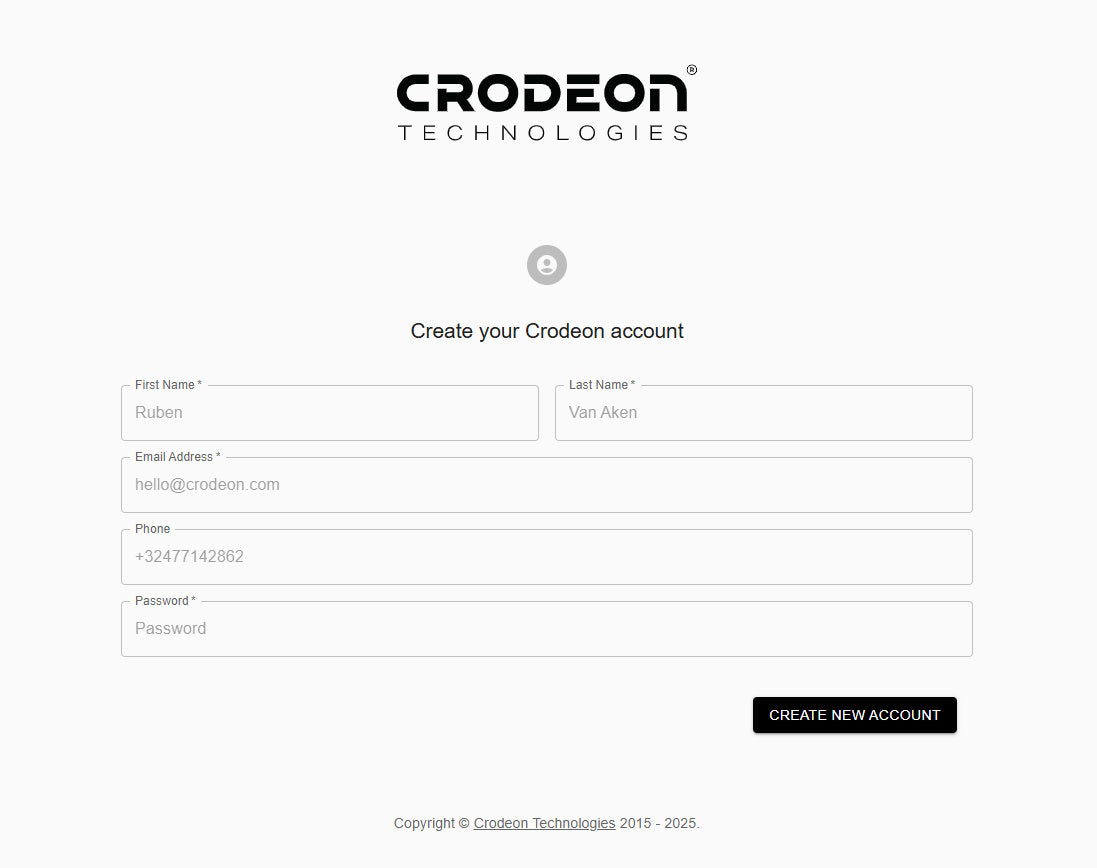

For professional applications, the absolute measurement at a specific moment is often less important than the consistency and reliability over a long period. A fixed monitoring system, such as Reporter®, is designed for stability. It uses high-quality, industrial sensors that measure from a fixed location, resulting in reliable data that you can act on and automate.

If you compare that data to a fast, flexible handheld meter? Know that you're comparing two different tools for two different purposes. Both can be correct within their own context and specifications.