Choose the right flow meter for your next water project

Flow meters are used to measure the flow in pipes. They can measure the amount of liquid water, gas, oil, etc flowing through a pipe at any given time. The composition and properties of this liquid determine the operation of a selected flow meter.

In this flow meter selection guide we'll go over some commonly used techniques and explain the pros and cons of these options. We also indicate for which applications these types of water flow meters can be used, and show some examples of common models.

How to select a flow meter

Which type of flow meter you will purchase depends on how you want to measure the flow of the liquid and what type of installation you have. Certain technical or legal provisions may also apply.

In general, it is important to pay attention to the setup, suitability requirements of the flow meter for the application, and accuracy.

- Set-up: Each flow meter has specific requirements for correct set-up. Accuracy is determined by how a liquid flows through the meter.

- Suitability requirements: A flow meter that functions perfectly on ultra-pure water may be unsuitable for more polluted water, but also vice versa: some measuring principles are completely unsuitable for ultra-pure water. This will also determine the maintenance cost to a significant extent.

- Accuracy: Each flow meter is usable in an interval, represented by the R-values. The flow meter can only be used within the minimum flow rate (Q1) and the maximum flow rate (Q3). The ratio (R) indicates the water flow meter accuracy.

- Online connection: Nowadays you really want to get remote access to the readings of your flow meter using an app or online dashboard. All of the meters covered in this article are compatible with Reporter, our real-time online data logger with built-in alarm engine.

Water meter comparison

The most common water flow meter types are mechanical water meters, ultrasonic flow meters, and electromagnetic flow meters. Each type has its own pros and cons.

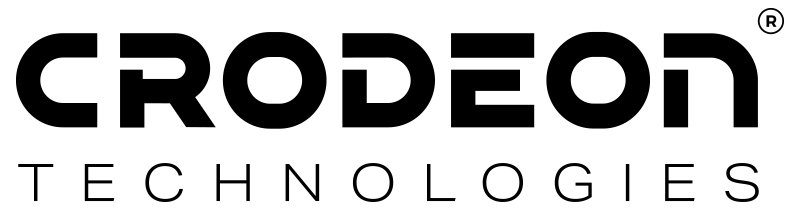

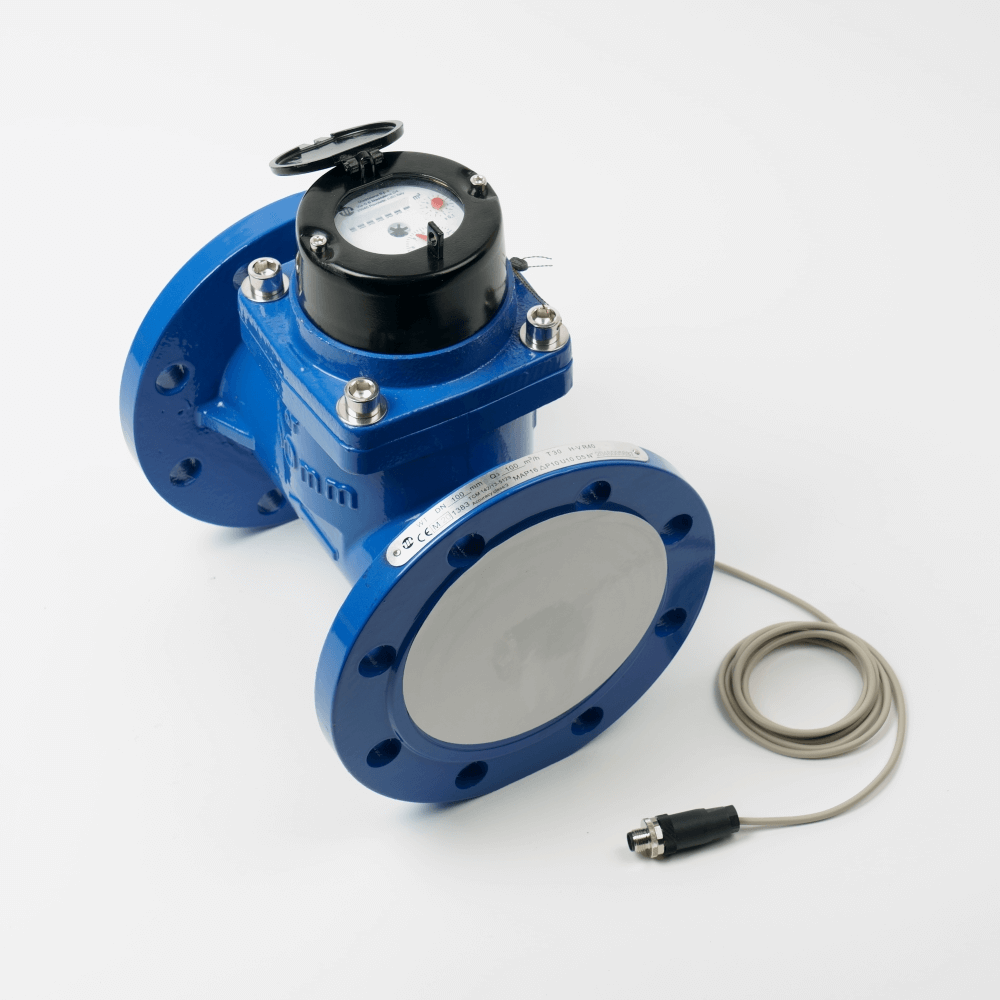

Mechanical Water Meters

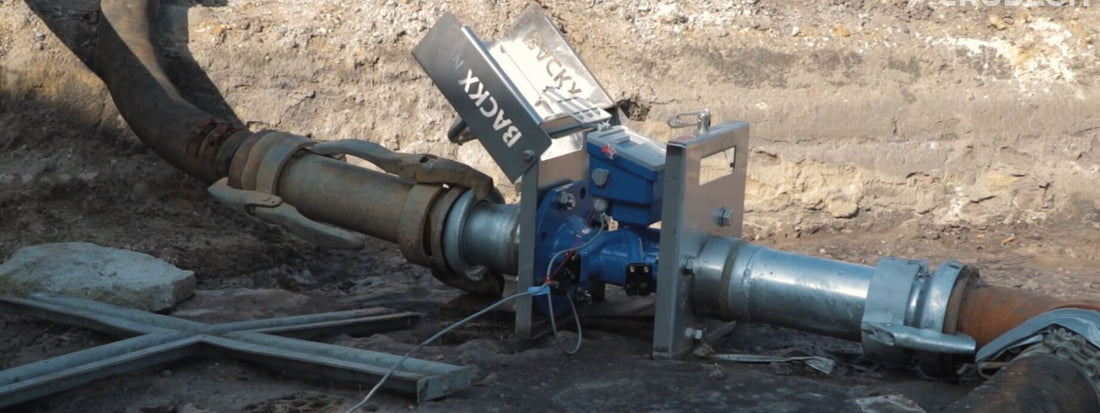

In mechanical water meters, the counter is controlled by the movement of a rotor located in the water. This type of meter is very common for flow meter projects and exists in all possible sizes.

The pros: The main advantage of mechanical water meters is the affordability, as they are generally priced much lower than the other types discussed below.

The cons: A mechanical flow meter is sensitive to contamination and wear. The mechanical wheel of a new flow meter turns smoothly, but over time, the build-up of dirt on the moving parts will slow the wheel rotation, negatively impacting the accuracy of the system.

If the water is heavily polluted, especially if it contains coarse particles such as stones or other objects, a mechanical flow meter can quickly become clogged or even break. As a result, these meters are only economical on sufficiently pure water and in stable conditions.

The types: With mechanical water meters we make a distinction between two water flow meter types, wet and dry. Wet types have a water-filled dial and dry types have a dry dial. The dry dial uses a magnetic mechanism to transfer the counts in the flow meter, without this mechanism coming directly into contact with the water. Especially in applications with strongly ferrous water, we recommend using dry meters, to prevent the counter from becoming illegible after a few months of use.

Accuracy: Dry dial mechanical water flow meters tend to be slightly less accurate than wet dial flow meters. Especially in the long run, this is due to the demagnetisation of dry dial flow meters. Use for calcareous or ferrous water will compromise accuracy and increase maintenance costs.

Ultrasonic Flow meters

Ultrasonic flow meters use ultrasonic waves to calculate flow through a pipe and are used to measure a variety of liquids, including water, natural gas, mineral oil, chemicals and dirty liquids.

The pros: An ultrasonic flow meter has no moving parts and thus requires little maintenance. These water meters are also cost effective, mainly because they are easy to install and operate. In addition, the measurements are not affected by extreme temperature fluctuations or changes in viscosity, density or pressure. These flow meters do not impede the flow, so they can be used on hygienic, corrosive and abrasive liquids.

The cons: An important condition, however, is the arrangement of the sensors in the flow meter: they are after all sensitive to contamination and it may be necessary to clean them periodically.

Accuracy: Ultrasonic measuring is an accurate and non-invasive measuring principle. An ultrasonic flow sensor provides an accurate measurement of flow for a wide variety of applications, including process control, water management and groundwater projects, as well as in the energy, chemical, food and beverage, pharmaceutical, metals and mining, pulp and paper, and oil and gas industries.

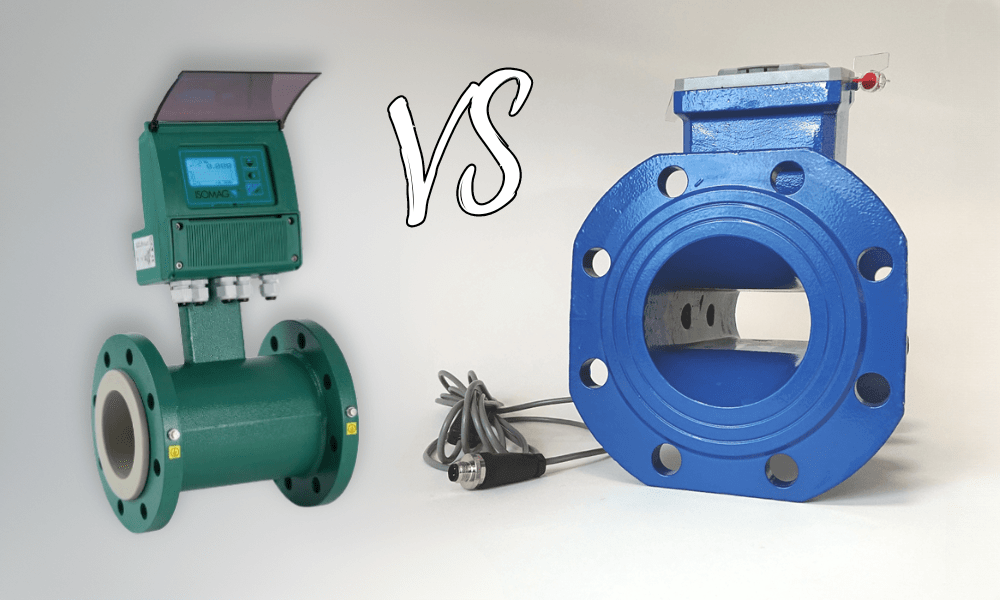

Electromagnetic Flow meters

This type of flow meter determines flow by measuring magnetic changes in a pipe. Such water meter uses Faraday's law and creates a magnetic field by passing electric current through a coil around the flow tube.

The pros: Like the ultrasonic flow meters, an electromagnetic sensor does not impede the flow. The sensors are located in the casing of the device: the inner pipe is therefore easy to maintain and there is much less risk of contamination of the sensors. The accuracy of the measurements is unaffected by viscosity, temperature and pressure, and the sensor responds well to rapid changes in flow.

The cons: A disadvantage is that you need to know (approximately) what the electrical conductivity of the liquid is. Rainwater, for example, has a lower conductivity than drinking water. If the conductivity is too low, the measurement may be wrong or not be performed at all.

The price tag of electromagnetic water meters is also a disadvantage. These types of sensors are generally quite a bit more expensive than mechanical water meters or ultrasonic water meters.

Accuracy: What is the most accurate type of flow meter? That's the electromagnetic flow meter, by a mile.

The measurement of an electromagnetic flow meter is more accurate than any other type of meter because both speed and volume are measured. This flow meter is very suitable for measuring conductive liquids such as water, acids or corrosive liquids.

What do you choose?

As you've been able to read in this guide how to select a flow meter depends on the purpose of your measuring project and what kind of liquid you want to measure.

We can also state that the cheapest flow meters do not necessarily come out as the best buy. Reliability, maintenance costs and the care for a correct set-up determine the actual cost.

At Crodeon we offer many different types of water flow meters for all kinds of applications. We always include a Reporter so you can keep track of the hourly flow and total flow using an online dashboard.

Read more about Smart Water monitoring or get in touch, we're here to help!