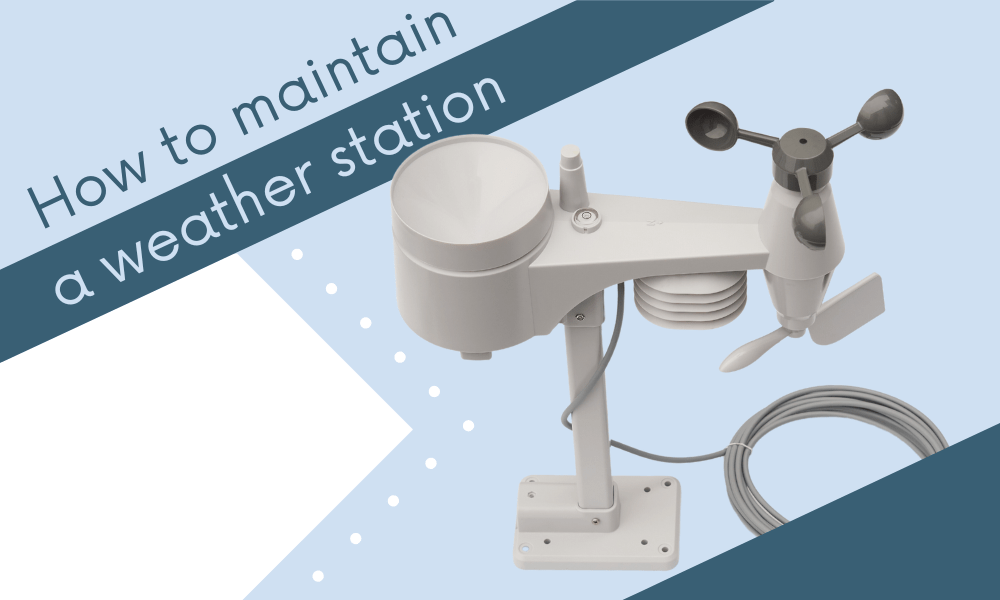

Weather Station Maintenance

Your weather station can last for many years, even more if you put some extra effort into your maintenance. In this guide we will help you through your yearly cleaning session.

Why do we need weather station maintenance?

A weather station should be checked yearly to ensure that all sensors are clean and working. An obstruction could affect your measurements and in the worst case, damage your installation. Parts that are cracked or damaged in other ways, should be replaced.

Another important thing to check is whether your installation is still positioned correctly and if any fastened elements haven't come loose.

Besides, several kinds of insects and small animals like to nest inside your weather station, and when this causes an obstruction in a sensor it becomes a problem.

- Birds can build a nest in the rain sensor

- Spiders can house in the temperature humidity sensor

Other parts of your weather station can become less functional when they are dirty or cluttered. Your solar panel for example can generate less electricity when it is covered in a layer of algae, grime or sand.

Before you start cleaning

- Disconnect the weather station from Reporter

- Start inspecting and cleaning

Temperature and humidity

In the Crodeon weather station, temperature and humidity* are measured by the Sensirion chip. These are precalibrated and do not require any other calibration throughout their lifetime. However, the outside (shield) of the sensor could become damaged or dirty. Dirt should be cleaned off the sensor shield with a damp cloth during weather station maintenance. If the shield is damaged the sensor should be replaced.

Bugs like itsy bitsy spider like to house in the sensor shield, but unfortunately, their nests make our measurements less accurate. Move the bugs and clean off webbings and other residues with a damp cloth to ensure that the airflow is not obstructed. You can also use a soft toothbrush.

- Remove unwanted guests living in your RH sensor's shield

- Check if the shield is still intact

During winter, ice and snow should be carefully removed from the shield.

*The sensor measures: temperature (dry bulb), wet bulb, dew point and relative humidity.

Wind speed (anemometer)

The wind speed sensor consists of three rotating cups. In order for the sensor to accurately measure windspeed, it should be able to rotate freely. If rotation stops too quickly the sensor is damaged and should be replaced.

To prevent your wind speed sensor from getting damaged you should check and clean it annually.

- Check if the anemometer still rotates supplely

- Remove any debris and constrictions (sand, cobwebs) that could hinder the movement of the anemometer

- Check if the three cups are still in good condition

If a cup is cracked or chafed, it can rotate out of balance. This affects the wind reading and gives incorrect measurements. A damaged sensor should be replaced.

During winter icicles can form on the weather station and the rotating parts could become stuck in place. Ice should be carefully removed until the weather sensors can move freely again. Be careful as the plastic of the sensors becomes more fragile when it's frozen.

Wind direction (wind vane)

During weather station maintenance it's important to check whether the wind vane is able to move freely in order to measure wind direction. If rotation stops too quickly the sensor is damaged and should be replaced. The wind vane will have a slightly larger resistance than the anemometer. At the same time, the North arrow (see image below) should be pointing North. If the weather sensor is not pointing to the North, any wind direction readings will be wrong.

- Check if the weather vane still rotates supplely

- Remove debris and constrictions from the vane

- Calibrate the sensor using the North arrow

The wind vane can be cleaned with warm soapy water and a cloth.

During winter icicles can form on the weather station and the rotating parts could become stuck in place. Ice should be carefully removed until the weather sensors can move freely again. Be careful as the plastic of the sensors becomes more fragile when it's frozen.

Rain sensor (tipping bucket)

Rain sensors are an essential part of any weather station. The sensor detects and measures rain through its ‘tipping bucket’ mechanism. The sensor (and funnel above it) however can become clogged with dirt and will have to be cleaned out if this is the case.

The rain sensor is a well-loved place for insects or birds to nest. Checking it during your annual weather station maintenance is vital. If you neglect to check and clean this part, your measurements will not be accurate.

- Check if there is no dirt, moss, leaves, wasp nest or bird's nest in the tipping bucket.

Cleaning the rain sensor can be done with some warm soapy water, the sensor should be thoroughly rinsed afterwards. To open the top of the sensor twist it counter-clockwise. If your sensor is heavily clogged, it might be wise to clean it out more than once a year. Especially in orchards or other places where an abundance of leaves might fall, a sensor might have to be cleaned out an extra time during Autumn.

The inside of the rain sensor should look like the image above. The little ‘spoon’ is the tipping bucket mechanism. Make sure that this mechanism can move freely and without resistance.

Pole & level

An integral part of your weather station set-up is the way it is attached. Whether your weather station is attached to a pole or to the edge of a roof, you will have to check whether it is still stable and standing upright.

- Is the weather station still level?

- Does the weather sensor not move around on the pole?

- Can the weather sensor shake or is it securely fastened?

When the weather sensor is not securely fastened, it may shake during storms. This disturbance can cause your measurements to become unreliable. The tipping bucket rain sensor may detect ‘rain’ when it's being hustled about and forcefully tipped over, even when there is no actual rain at all.

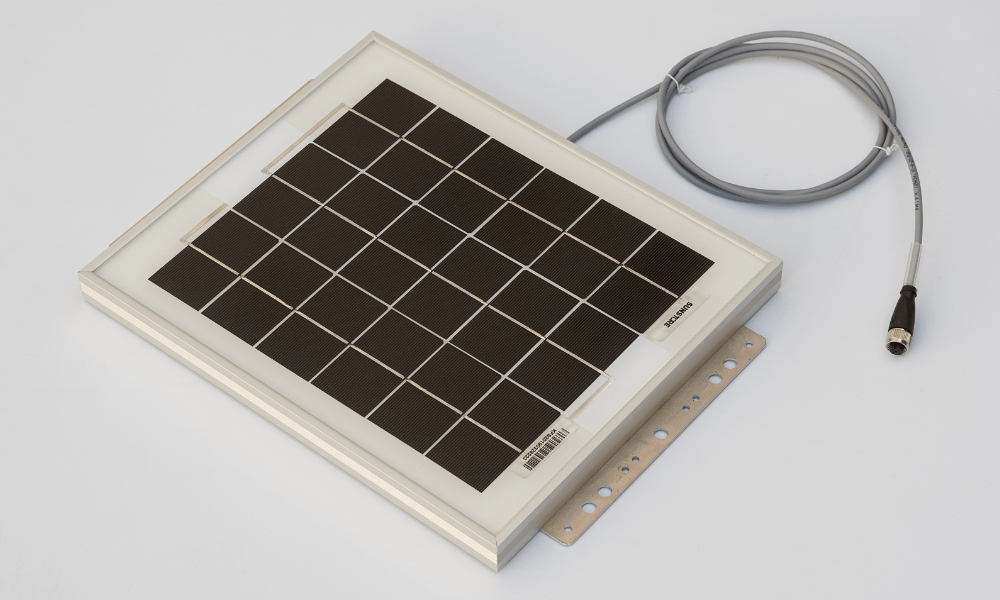

Solar panel

Without power your weather station is useless, ensuring that the solar panel is functioning correctly is an essential part of your weather station maintenance plan. In order for the solar panel to work, it must be clean, undamaged and facing the direction with the most daylight.

- Check if the surface of the solar panel is clean

- Check if the surface of the panel is undamaged

- Check if the solar panel is still facing the direction with the most daylight

Any grime, algae, moss, sand or other dirt should be cleaned off the solar panel. To do this you may use a damp cloth with soapy water or even an alcohol wipe.

Hail, storms, frost and rain can cause damage to the surface of the solar panel. Even birds sometimes drop a pebble which can crack your panel. A damaged solar panel does not generate sufficient power and should be replaced.

Reporter

When you're done checking your weather sensor and solar panel, it's important to also check up on your sensor module itself.

- Make sure that Reporter's casing is undamaged, a broken or cracked casing is no longer water and weatherproof

- Make sure that none of the screws, bolts or attachment points of Reporter came loose

Reporter came with five dust caps to protect the connectors and keep them free from water, debris, dust or other kinds of dirt. Of course you will need to remove the dust caps when connecting a sensor or power cable, but when a connector is not in use a dust cap must be used.

The dust caps come with a silicone lining which ensures that water nor dirt can enter the inside of your Reporter.

- Make sure that the dust caps of unused connectors are securely tightened

- Check if the dust caps are undamaged (broken or cracked caps should be replaced)

If your casing or dust caps are damaged, please take Reporter inside and contact us as soon as possible.

After your weather station maintenance

When you're done cleaning your weather sensor, it's time to reconnect it to Reporter.

- Check whether your cable is plugged in and securely fastened to the connector

- Check if new weather data is streamed to the Dashboard

- Double-check the North arrow and spirit level of the weather station

You're done cleaning your weather station. Please don't hesitate to contact us through the form on this page if you still have a question regarding the maintenance of your installation.

You might also be interested in:

FAQ

How do you take care of weather instruments?

Check to make sure that rotating parts of a weather station can move supplely. Spider webs, debris, leaves or other dirt should be removed. Most parts of your weather station can be cleaned with a damp cloth with warm soapy water. You will need to carry out maintenance at least once a year to make sure that all parts of your weather station still function as they should.

What is the maintenance of wind vane?

A wind vane requires a specific kind of maintenance. Firstly, the vane itself should be checked. Make sure that it rotates supplely and that no dirt or debris is hindering the movement. Secondly, the North arrow on the sensor that calibrates the wind direction should be checked. If the arrow does not point North, any measurement will be incorrect.

What is the proper care or maintenance of rain gauge?

A rain gauge, rain sensor or tipping bucket mechanism should be checked and cleaned regularly. Birds, spiders and other small animals like to nest inside of the sensor. Dirt, leaves, moss and other debris can fall down the funnel and build up on the inside of the sensor, hindering the tipping bucket. To properly clean your rain sensor you should open it. Twist counter-clockwise, remove any debris, wash the inside with warm soapy water and then rinse until clean.

Maintenance of anemometer

An anemometer measures wind speed, but when a sensor cannot rotate as supplely as it should, those measurements are off. The maintenance of an anemometer requires the following: a visual check to see if there is any dirt hindering movement and if so remove the dirt. A physical check to see if the rotating cups move smoothly, if they do not the sensor should be replaced.