Monitoring heat treatment in cargo containers

When treating containers that are destined to travel overseas, fumigation or an alternative for fumigation is necessary to ensure that no live organisms accidentally travel along. This treatment is carried out in the harbour before the cargo is exported. When using heat treatment it's crucial to monitor the temperature inside of the container with a temperature sensor, to make sure the temperature actually stays stable at the minimum temperature or slightly higher.

In this article, we discuss the advantages of heat treatment and why monitoring the temperature inside the container is crucial.

Why is heat treatment of cargo containers necessary?

Cargo is often shipped on wooden pallets. Wood tends to attract all sorts of different insects. This is all fine when goods are shipped within the same zone, but becomes dangerous when cargo is exported to other continents. Native insects can become dangerous invasive species that endanger ecosystems and agriculture.

When goods are shipped all over the world there's always a chance for some stowaways to come along. A well-known and unwanted passenger is the Brown Marmorated Stink Bug (BMSB). These bugs are especially being barred from Australia and New Zealand. Not only insects can pose a risk, moulds, microorganisms, reptiles and small mammals have travelled along in the past, spreading disease in their host country.

To kill stink bugs and other pests, treatment of containers is necessary. This process is called fumigation. This treatment takes place in the country of origin where the goods leave the harbour.

The dangers of fumigation

In the past, the toxic gas methyl bromide was used to sanitise shipping containers, but as it turned out it was more harmful than expected. Not only does it eradicate the pests in the container, but it's also harmful to the workers who later on have to inspect the cargo. Methyl bromide is detrimental to the environment and is nowadays banned in parts of the world. The gas also tends to pollute the air and soil where it disperses. Even the tiniest bit of residue could cause serious harm to the central nervous system, along with different kinds of brain damage and lung damage. Besides, even the ozone layer turned out to be weakened by it.

An alternative for fumigation turned out to be long overdue.

The alternative: heat treatment

An alternative treatment to fumigation with toxic gases is heat treatment. During this process, the contents of a cargo container are heated to their core to 56°C. This requires that the inside of the container reaches at least 60°C for a minimum of 30 minutes. This ensures that bugs such as BMSB are dead, along with their eggs and larvae.

Important to note is that if the core temperature of 56°C fails to be reached and kept for 30 minutes, the treatment is considered unsuccessful. Remote monitoring of temperature is therefore crucial, to make sure that possible pests are eradicated.

The advantages of heat treatment

The advantage of heat-treating cargo instead of classic fumigation is that the use of dangerous and toxic gases is no longer necessary. It is significantly more environmentally friendly and easier to manage after the treatment: degassing is unnecessary, and staff can safely enter the container. Of course, treatment with high temperatures is only possible when the goods that are transported can withstand this high heat.

Once the heat treatment of the container is completed, the container is simply opened to allows its contents to cool down to the surrounding temperature. The packaging gets marked with a special HT stamp and the shipment gets the documents and certificates that are needed. The container will be resealed and is ready for export.

Monitoring heat treatments

Monitoring heat treatment of cargo is conducted by placing multiple temperature sensors, deep into the cargo to register the temperature in the coldest places. Temperature is recorded, and when the minimum values are successfully kept, the container is ready to move along.

Monitoring heat treatment of cargo containers with multiple sensors allows for better accuracy and precision in measuring temperature gradients and distribution within the container. This ensures that the entire cargo is uniformly heated. It also helps identify potential hot spots or cold spots, enabling adjustments to be made to the heat treatment process to ensure effective treatment.

A real-time monitoring sensor module can continuously record the temperature inside of the container for the entire 30 minutes. The live data allows you to instantly make adjustments were needed.

When a treatment fails to maintain a core temperature of at least 56°C for 30 minutes, the cargo cannot be exported. The entire process will have to be repeated, causing delays. To ensure a smooth running process in the port, it's vital that these failures can't happen.

Our solution for successful heat treatment

Such a monitoring system is Reporter, the versatile remote monitoring plug & play system. Reporter comes with an autonomous internet connection through a SIM card and is able to work on both grid power and its own solar panel. As the system is mobile, it can be used in multiple locations. Reporter sends its data to the cloud (Crodeon Dashboard) at intervals of 30 seconds or more. After the treatment, all of the exact data and measurements can be presented for record keeping.

The beauty of Reporter is that it's able to be used by everyone. No technical knowledge is needed and the installation is fast & easy.

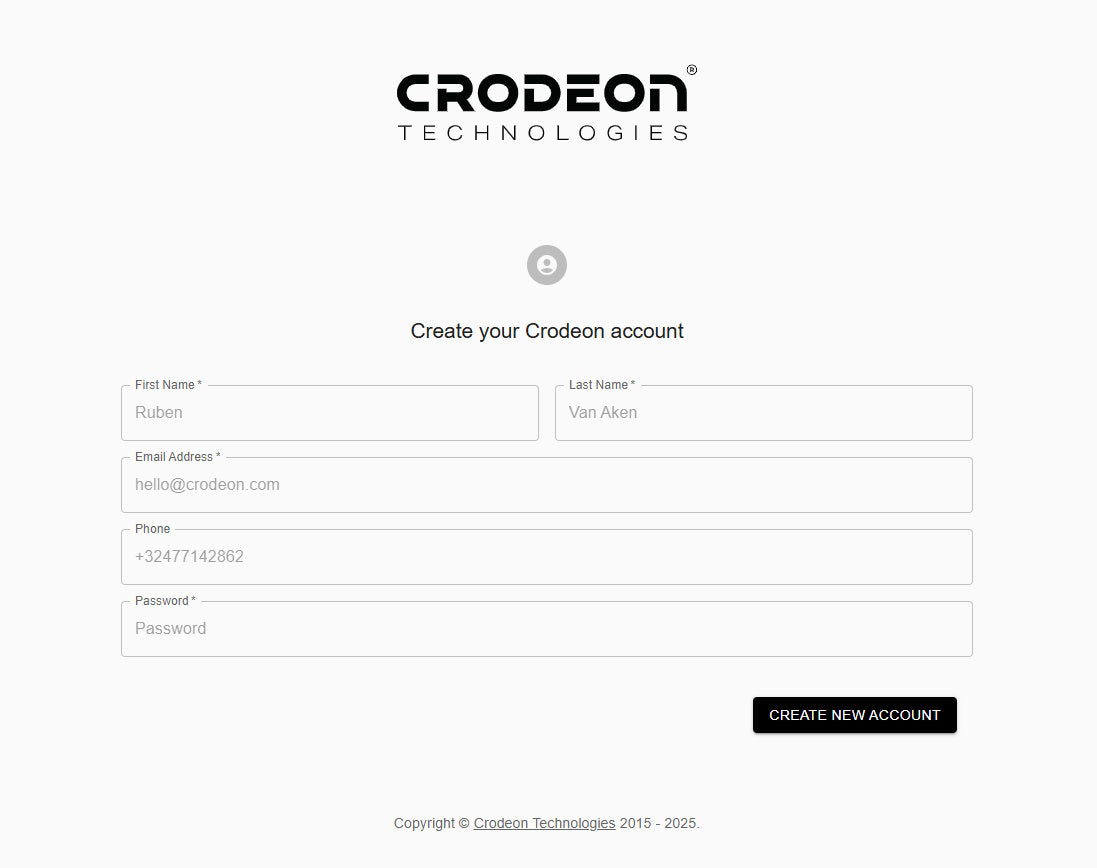

The Crodeon Dashboard

The Crodeon Dashboard is a web application that you can access through your favourite browser. This online cloud platform allows you change Reporter settings, alter measuring intervals and view live and historical data.

Historical data can be exported to Excel, giving you the opportunity to analyse it in close detail if needed. These records could be especially valuable if it would ever be necessary to prove that a shipment was really subjected to 56°C for 30 minutes.

Start monitoring heat treatments today

Whether you ship goods globally, operate a major harbour, or perform heat treatments, Reporter is your mobile and reliable remote monitoring solution.

Contact us to discuss our services. Send us an email or give Jonathan a call.

Sources:

Aigner, J. D., & Kuhar, T. P. (2016). Lethal High Temperature Extremes of the Brown Marmorated Stink Bug (Hemiptera: Pentatomidae) and Efficacy of Commercial Heat Treatments for Control in Export Shipping Cargo1. Journal of Agricultural and Urban Entomology, 32(1), 1–6. https://doi.org/10.3954/1523-5475-32.1.1

Read more: