Quickly tackle the 7 principles of HACCP

On the Crodeon website we already talk about HACCP and why you should pay attention to food safety. In this blog we'll explain how today's technology can help you tackle the 7 principles of HACCP. We'll use our own sensor device called Reporter® as a concrete example for a food monitoring system.

These are the HACCP guidelines for restaurants and other food production facilities, that help keep your kitchen, production line or storage safe.

- Principle 1: Conduct a hazard analysis.

- Principle 2: Determine the critical control points (CCPs).

- Principle 3: Establish critical limits.

- Principle 4: Establish monitoring procedures.

- Principle 5: Establish corrective actions.

- Principle 6: Establish verification procedures.

- Principle 7: Establish record-keeping and documentation procedures.

Principle 1: Conduct a hazard analysis (HA)

What is this about?

Establish a list of potential dangers and identify the people in your organisation that are involved in the food monitoring. Sort these risks by assigning a severity score to each hazard. Some examples of potential dangers are bacterial growth, contaminated packaging and faulty food storage temperatures.

How can your Reporter® tackle this?

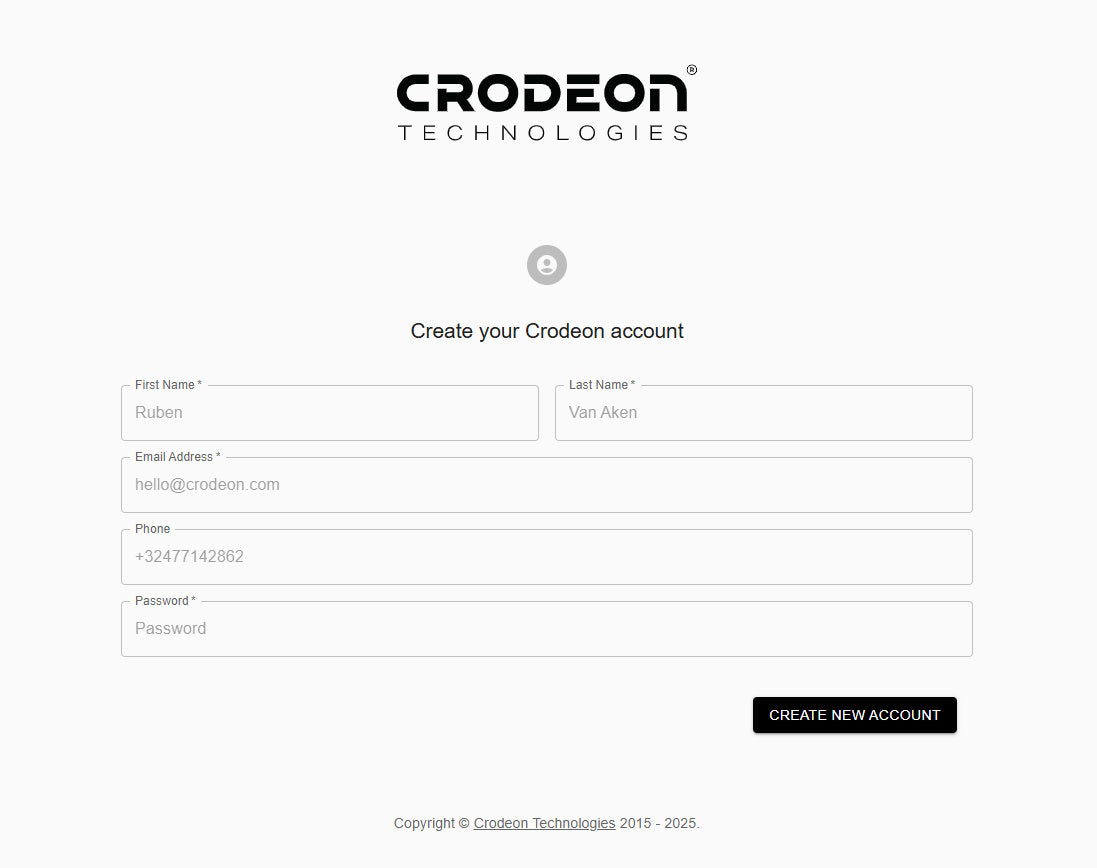

Reporter can help you with temperature monitoring and with setting up your team. Use the Crodeon Dashboard to configure alarm settings and determine who needs to receive the first notification. When this person can't take care of the incident, the message can automatically be forwarded to the next person in line. After these steps you can then start with the hazard identification and hazard evaluation.

Principle 2: Determine the critical control points (CCPs)

What is this about?

After establishing the list of potential hazards, the next step is to determine the identified hazards that could compromise the safety and hygienic quality of food. These hazards need to be controlled and are therefore called Critical Control Points. To help follow the HACCP guidelines for restaurants or other food facilities you should pay attention to temperature registration. This is a clear preventative measure for this hazard.

How can your Reporter® tackle this?

Reporter can help you with real-time online temperature registration. The device has up to four wired sensors that can be extended up to 30 meter. All measurements are available in real-time and on your pc, smartphone or tablet. The most common measurements for food monitoring in food storage are temperature, humidity and power failure. Make sure you install the temperature sensors in a place that is representative for the entire room. For example, don't place them near the door or the evaporator.

Principle 3: Establish critical limits

What is this about?

This principle is about determining the limits of acceptability or non-acceptability of a risk and setting tolerance limit values to ensure food safety. When the analysis reveals that the dangers or risks exceed the critical thresholds, this means that there is a real risk of endangering the lives of consumers. Concerning food storage, this involves setting a maximum and minimum storage temperature. Other frequent examples of limits could be expiration dates, the consumption period or the cooking temperature.

How can your Reporter® tackle this?

Reporter allows you to configure maximum and minimum thresholds using the Crodeon Dashboard. You can do this for every sensor parameter and even add a delay when necessary. When the critical limit is exceeded for a period longer than the delay, the person in charge will be notified. Helping you with your food safety monitoring processes.

Principle 4: Establish HACCP monitoring procedures

What is this about?

HACCP monitoring procedures can help you to prevent the risks that you have identified. Food storage typically needs an alarm to help you keep an eye on the temperatures. The alarm will be triggered if the temperature rises above a certain threshold. This measure is sufficient proof that you have made every effort to control this critical control point and follow the HACCP guidelines for restaurants.

How can your Reporter® tackle this?

Monitor your cold room or cold storage using just one Reporter. You can view and access real-time and historical data using pc, tablet and smartphone. Configure the measurement interval anywhere between 30 seconds and 2 hours. The recommended interval is 5 minutes. The Crodeon Dashboard allows you to name your Reporter as well as each individual sensor.

Principle 5: Establish corrective actions

What is this about?

When food safety monitoring processes reveal that a Critical Control Point is not within limits, corrective measures should be established. All corrective measures must be recorded in the documentation.

How can your Reporter® tackle this?

Using the Crodeon Dashboard you can manage the responsible HACCP monitoring person for each area where a Reporter or sensor is installed and corrective measures have to be established. Adding or deleting users on the Dashboard is as simple as a touch on your screen. You can assign a role to new users, so they can only view data as a viewer or manage the configuration of the system as editors or owners.

Principle 6: Establish verification procedures

What is this about?

To confirm the effectiveness of the food safety monitoring processes, it is essential to carry out verification measures. For example, you should verify whether the calibration of the thermometer that validates the temperature of the cold room is correct. Make sure that every member of your staff is aware of the rules that you enforce for HACCP monitoring.

How can your Reporter® tackle this?

The Crodeon Dashboard allows you to manage the verification process of your exceedances. Every exceedance is stored in the cloud along with its timestamp. You can always check the duration of an exceedance and who has confirmed the receipt of the alarm notification.

Principle 7: Establish record-keeping and documentation procedures

What is this about?

The various procedures, methods and records that have been created as part of the HACCP guidelines for restaurants and HACCP implementation must be archived so they can be consulted by the authorities in the event of an inspection. For the food monitoring system to be implemented effectively, it is essential that the entire catering staff is trained in the 7 principles of HACCP.

How can your Reporter® tackle this?

Using the Crodeon Dashboard, historical measurement data is automatically stored in the cloud. At any moment you can download your measurement data as csv file, so you can use Excel or any other spreadsheet tool to analyse the data. In the Exceedances tab you can also view a list of all temperature exceedances, indicating at which times and for how long the temperature has exceeded the configured thresholds.

Get in touch if you have any questions about online temperature registration for the 7 principles of HACCP. Browse our shop for more information about Reporter® and our sensors. Also check out these 6 HACCP lists.