Remote pump monitoring

Remote pump monitoring reduces costs as the need for manual interventions is greatly reduced and limited to when maintenance is absolutely necessary. A pump monitoring unit monitors different parameters like flow, energy consumption, temperature, pressure and more. These parameters can indicate a problem with the pump, allowing for immediate action.

Time is scarce, and skilled technicians are expensive, which is why it's efficient to employ a water pump monitoring system that keeps an eye on your pumps.

Save money with remote pump monitoring

In-person, on-site visits can be costly, so let's limit them to when they're truly necessary.

A remote pump monitoring system lets you analyse your pump's health from afar. This gives you the opportunity to plan on-site visits for when maintenance is needed, cutting down on unnecessary manual interventions. As an added bonus, the pump monitoring system gives accurate real-time data 24/7 about what problems a pump might be having, giving the maintenance team a head start to tackle the issue and prevent or limit downtime of the machine.

- On-site visits only when needed

- Less downtime

- Live data 24/7

Slash power bills and increase energy efficiency

A malfunctioning pump will use more electricity than needed, racking up your energy bills. By monitoring the power of your pump with an energy consumption meter, you can detect changes in your pump's power consumption and take immediate action. Optimising your pump's energy consumption for maximum efficiency is now a piece of cake!

Predictive and proactive maintenance made easy

Comparing historical measurements with live data through continuous pump surveillance enables you to discover trends and anomalies. This lets you reduce labour time and improve response efficiency.

Pump health monitoring

When your pump starts behaving oddly or taking way longer than expected to complete a task, you want a technician to be on site as soon as possible. Real-time pump condition monitoring enables predictive maintenance and proactive maintenance:

- Is the pump overheating?

- Has pressure suddenly dropped?

- Is the outflow lower than expected?

- Is the energy consumption skyrocketing?

All these insights give the maintenance team a good idea of what might be wrong with the pump.

Quick interventions prevent further damage and expensive breakdowns. By limiting maintenance to only when needed, you reduce unneeded manual labour and travel costs.

Know your pump health at all times

Remote pump performance monitoring allows for quick interventions and prevents costly failures, which is why reliable 24/7 data is simply a must. Reporter, our plug & play sensor device for remote monitoring, is ready to keep an eye on your pumps!

Reporter is compatible with multiple power options: grid power, battery pack, and solar panel. The system can even detect power outages while staying operational through its internal battery, ideal for pump power monitoring. An internet connection is established through its integrated SIM card (cellular data 2G/4G/5G LTE-M, NB-IoT & Cat-M), giving you internet access in even the most remote locations.

Real-time remote access, anywhere, anytime

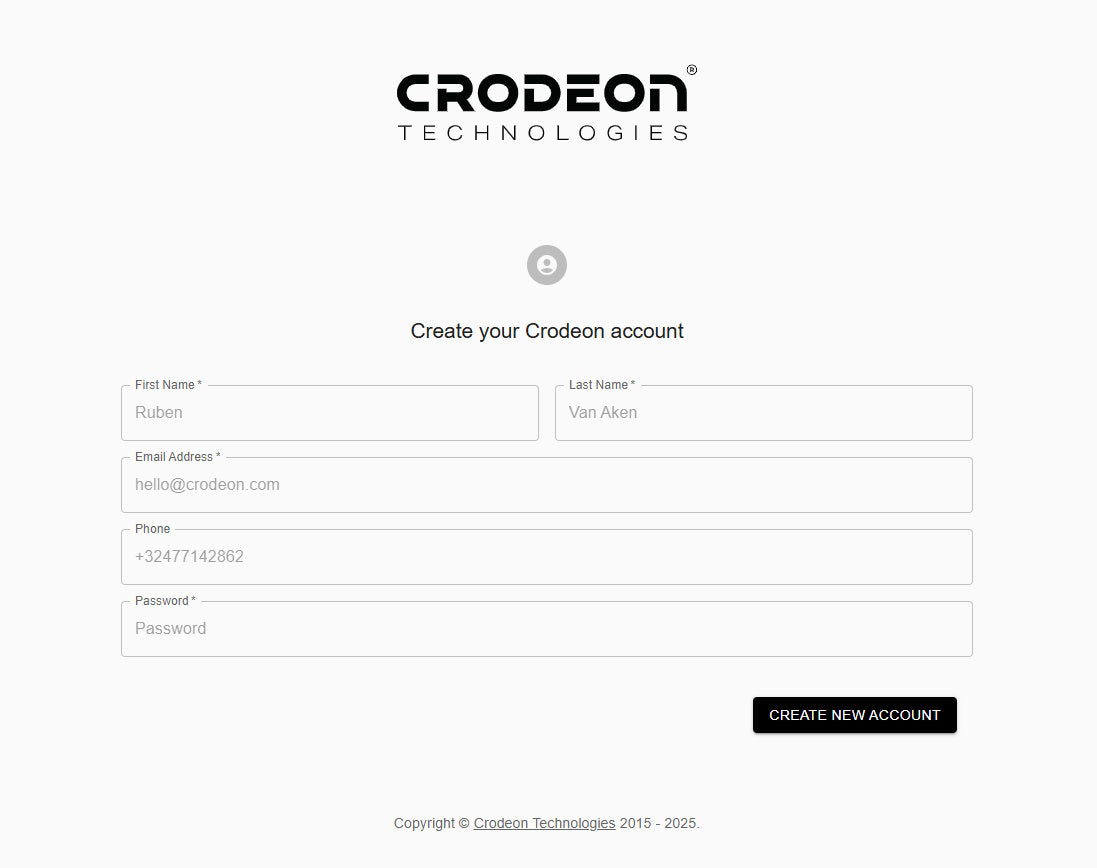

Reporter streams all live measurements to the Crodeon Dashboard (our user-friendly cloud platform), where data is visualised and stored. The Crodeon Dashboard is accessible 24/7 through your browser of choice on your cellphone, PC, tablet, etc. No custom software installation is needed for this water pump monitoring system. Historical data can be downloaded by means of a .csv file and opened in Excel.

Through our REST API you can integrate both live and historical data into third-party platforms or software. This allows for smooth data analysis and data-based maintenance planning.

All Reporter settings, sensor settings, and the configuration of alarm notifications happen in the cloud.

Smart alarms that notify you instantly

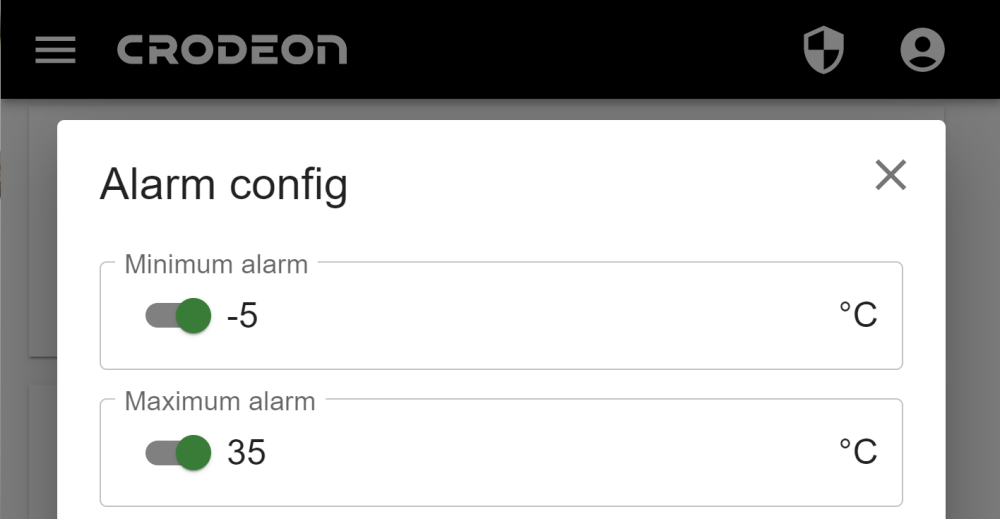

On the Crodeon Dashboard you can configure alarm notifications and personalise them to your needs. Receive a voice call, text message, or email when things go awry so you can take immediate action and prevent irreparable damages.

You can select either simple alarms, or cascading alarms that will warn multiple people until someone confirms the alarm.

Key parameters to monitor for better pump performance

Some parameters are more useful to monitor than others when it comes to pump performance monitoring. We'll give an overview of relevant monitoring parameters for pump health monitoring.

- Flow rate: a decreased flow rate can indicate that there might be a blockage or that the pump is unable to handle as much liquid as it previously could.

- Temperature: overheating might point to a lack of proper lubrication inside of the pump, indicating that an oil change is overdue.

- Energy consumption: a sudden increase in electricity use might indicate that the pump is malfunctioning and needs to be repaired.

-

Pressure: a drop in pressure might indicate that the pump is leaking liquid somewhere. A spike in pressure can point to clogged filters or blockages.

- Leaks: special leak sensors can see a pool of liquid forming on a surface.

- Valve position: tilt sensors and/or limit switches can measure the position of valves in a sewer system for example, indicating whether something is closed when it shouldn't be.

- Level: monitoring the level of a basin can help you determine whether pumping is necessary or if it could also be delayed until energy prices are down (at night for example).

Choosing the right remote pump monitoring system

You must make sure the system you choose to monitor your pump answers to your monitoring needs. The following parameters are must-haves when it comes to IoT pump monitoring.

- Remote data access: you need to be able to see live data at all times. Both for maintenance purposes and cost savings.

- Reliable data logging and storing: your data logger must have a secure connection to the cloud with ample storage capacities.

- Alarm notifications: your monitoring device must be able to trigger alarm notifications when your pump is malfunctioning.

- Wide compatibility with pumps and sensors: your system must be able to connect to various sensors that use different protocols.

- API access: your sensor device must be able to connect to third-party platforms for smooth data analysis.

- GPS localisation: accurate location data is useful for knowing which pump where is in need of an intervention.

- Plug & Play sensor connection: high-skilled technicians are expensive, which is why a system with intuitive plug & play sensor connection is vital.

Reporter

Reporter is a wireless pump monitoring system that offers user-friendly installation that can be done by anyone. The straightforward and intuitive design of the Crodeon Dashboard allows for easy set-up to get the project up and running in no time. 24/7 access to real-time data in the Dashboard ensures that you stay up-to-date wherever you are.

Crodeon offers complete monitoring of the pump, complete with alarm notifications, with the option of additional (unrelated) sensors when desired. Reporter is compatible with almost any sensor thanks to our sensor adapters.

The Crodeon API makes analysis possible by connecting the measuring data to third-party software. Due to the built-in GPS chip, the location of Reporter can be tracked through the Crodeon Dashboard.

Optimise pump station operations with telemetry

Managing pump stations efficiently requires more than just manual checks, it demands real-time visibility and intelligent automation. That's where a reliable pump station telemetry system like Reporter makes all the difference.

With remote pump station monitoring, you gain 24/7 access to live performance data, enabling quick decisions, early detection of faults, and reduced need for on-site visits. Whether you're overseeing a single location or a network of pumps, pump station monitoring through Reporter ensures smoother operations, fewer surprises, and more control from anywhere.

Embrace data-driven pump management

Remote pump monitoring empowers you to take control of your operations with real-time insights and predictive maintenance. By using continuous data collection and smart alarms, you can significantly reduce downtime, lower maintenance costs, and boost energy efficiency.

The result? Smarter, more reliable pump station performance, without the need for constant on-site intervention.

Discover how our remote monitoring solutions can transform your pump systems and start saving time, energy, and money today.